SPC Software

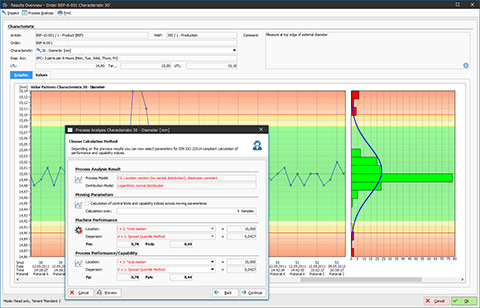

The SPC software Compact.Net supports you in monitoring your manufacturing processes and controlling them based on pre-specified warning thresholds and control limits.

Statistical Process Control in the quality inspection software Compact.Net

Statistical Process Control in the quality inspection software Compact.Net

The software provides standard-compliant incoming goods inspection plans that facilitate adherence to ISO 2859 and ISO 3951 in all their modes (normal, increased, reduced, etc.), flexible skip-lot-methods, or freely definable and process-accompanying inspections. From individual requirements inspections and freely definable interval inspections with any number of qualitative or quantitative characteristics to mathematically complex and precisely formulated statistical process control (SPC) – the software offers you a vast range of inspection possibilities. These include detailed and scalable test methods, which fully automatically check your processes for outliers, trends, runs, or any other type of effect and alert you or a predefined group of persons if process or tolerance thresholds are violated or any other type of process anomaly occurs.

Individual Sampling Plans

Use the SPC Software to freely design sampling plans, define new and unlimited characteristic specifications with the integrated mathematical and statistical formulae, or apply the variety of predefined characteristic types available – from simple ok / not ok decisions to sophisticated and structured classifying list characteristics. Integrate graphics, videos, and drawings into your inspection plans or refer to further applicable internal / external documents, audits, job and procedural orders in order to provide the individual processor or inspector with the information he requires at any point in time.

Flexible Inspection Frequencies

The frequency of the inspection can also be defined individually. Apart from standard inspection frequencies, the SPC Software also allows you to apply so-called shift-models. These enable you to tailor the inspection intervals to precisely correspond to the work-shifts of your employees. Once the inspection plan has been completed, the software allows you to test it in a realistic test environment (sandbox) prior to putting it into practice.

The application as SPC Software is only one part of the Quality Inspection Software Compact.Net, which combines all aspects of quality assurance within one solution.